Need help? Call us:

+91 73558-02025

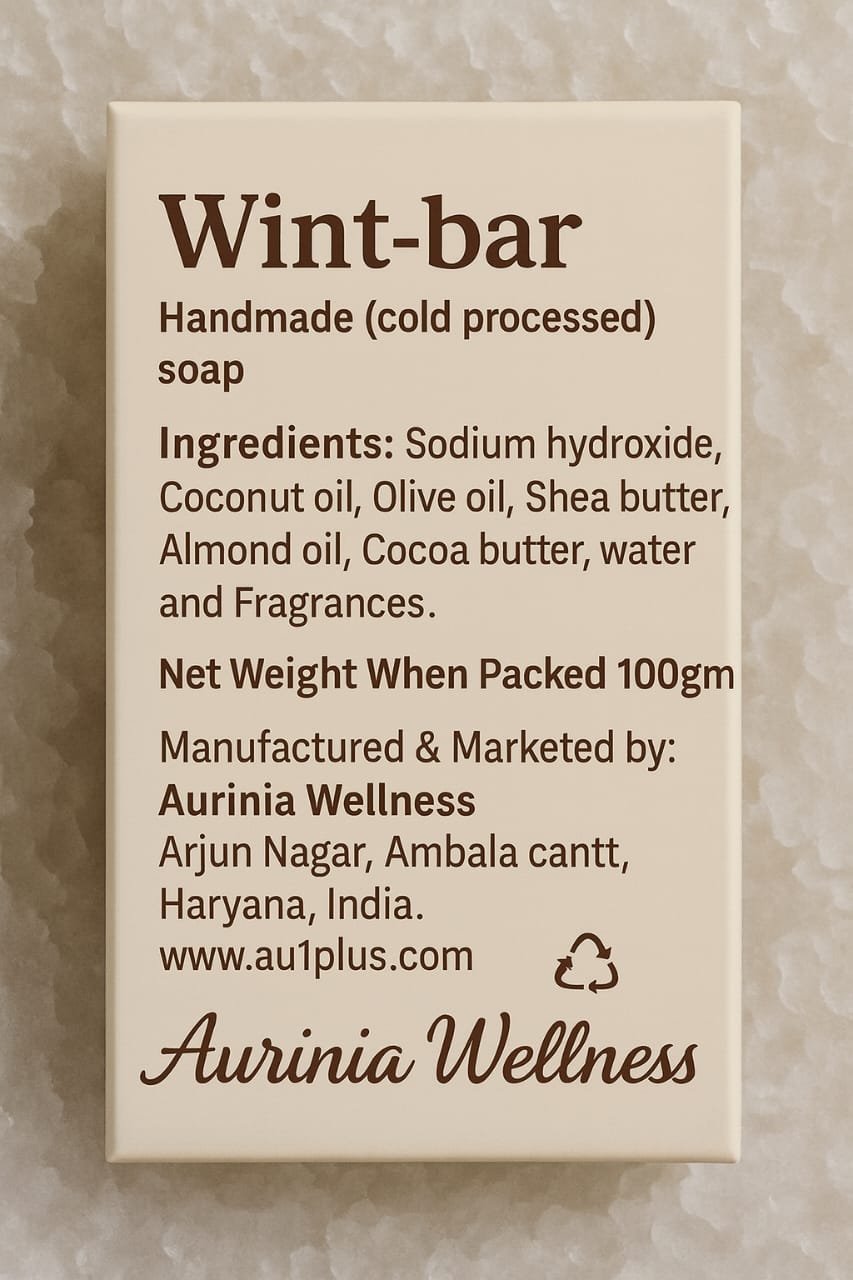

Wint-bar BATH SOAP

Have any Questions?

Feel free to Get in touch

The Art of Cold Process Soap Making

Cold process soap making is a traditional method that creates a superior, nourishing soap bar. Unlike commercial soaps that often strip away beneficial ingredients, the cold process method preserves the natural properties of oils and butters by not applying external heat. This technique allows the saponification process—that turns oils into soap—to occur naturally over several weeks, resulting in a gentle, conditioning bar.

The cold process method is key to maintaining the unique benefits of each ingredient in the soap. Here’s how it preserves the properties of three of the most important components:

Coconut Oil: In a cold process soap, the fatty acids from the coconut oil are preserved, which are responsible for its robust, bubbly lather. This allows the soap to be an excellent cleanser without stripping the skin of its natural moisture. The oil’s moisturizing properties are retained, ensuring the soap provides a creamy feel.

Olive Oil: Known for its gentle, moisturizing qualities, olive oil is a cornerstone of many high-quality soaps. The cold process method ensures that the squalene and polyphenols naturally present in olive oil are not destroyed by high temperatures. These compounds are excellent skin conditioners and antioxidants, leaving the skin feeling soft and supple.

Shea Butter: A powerhouse of hydration, shea butter contains a high concentration of fatty acids and vitamins (A, E, and F). The cold process technique keeps these nutrients intact, allowing the butter to deliver deep nourishment to the skin. This helps to restore and protect the skin’s natural barrier, making the soap particularly beneficial for dry or sensitive skin.

By avoiding high heat, the cold process method ensures that these valuable ingredients remain effective, providing a soap that not only cleanses but also deeply conditions and nourishes the skin.

Neera-bar BATH SOAP

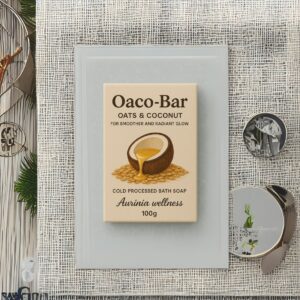

Oaco-Bar OATS & COCONUT FOR SMOOTHER AND RADIANT GLOW

Oud-Bar Bath Soap

Related products

Oud-Bar Bath Soap

Neera-bar BATH SOAP

You may add any content here from XStore Control Panel->Sales booster->Request a quote->Ask a question notification

At sem a enim eu vulputate nullam convallis Iaculis vitae odio faucibus adipiscing urna.

Reviews

There are no reviews yet.